Plug Into More Green Stock News

Tap into the pulse of emerging green sectors every morning. Top daily headlines from clean energy, cleantech, cannabis, and sustainable transport stocks:

Graphex Group Enters into MOU with ReCharge Global to Develop Graphite Manufacturing Facilities for Mine-to-Battery Graphite Supply to the EV Industry

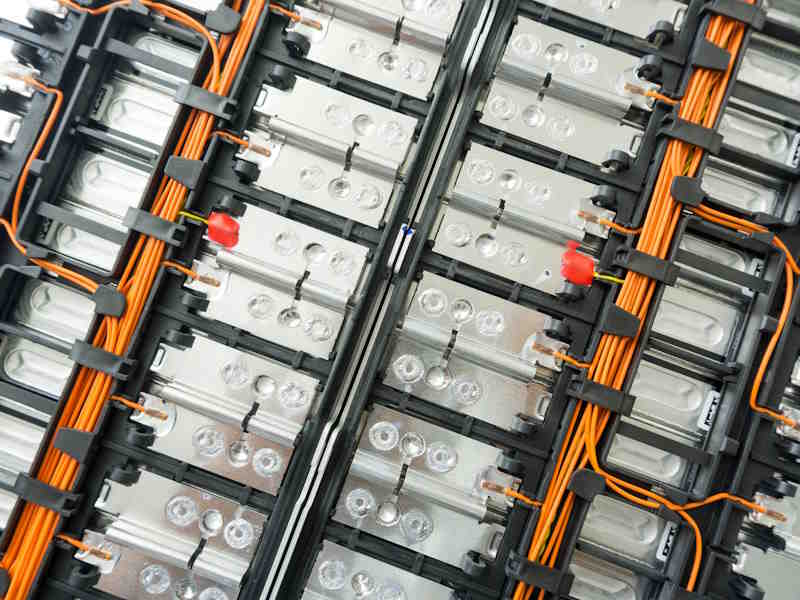

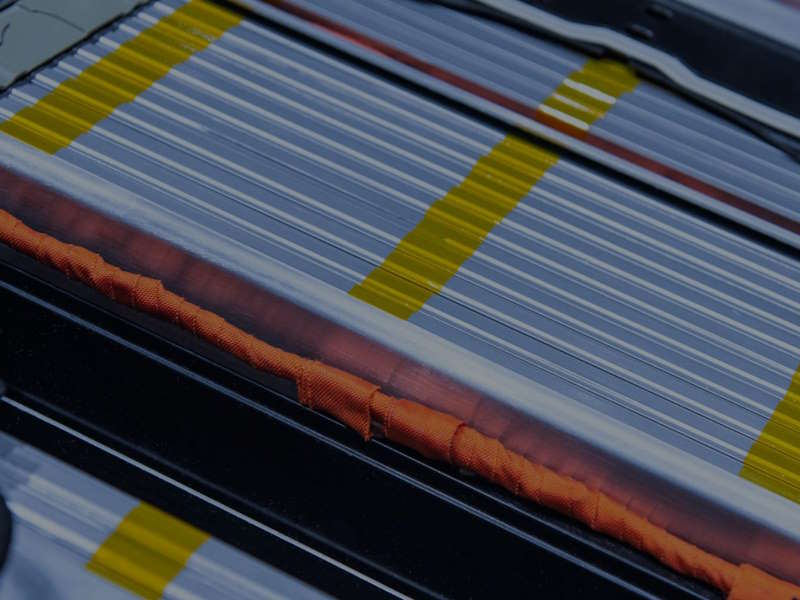

Graphex Technologies, LLC, a wholly owned subsidiary of Graphex Group Limited (collectively “Graphex”) (NYSE American: GRFX | HKSE: 6128) and a global leader in mid-stream processing of natural graphite for use in lithium-ion (Li-ion) power batteries, announced today that it has entered into a non-binding Memorandum of Understanding (“MOU”) with ReCharge Global Corp. (“ReCharge”), an innovative team providing key feedstock and critical minerals for the production of electric vehicle (EV) Li-ion power batteries to the global EV industry.

ReCharge was founded by the team that developed one of the first Li-ion battery recycling technologies for North American OEM’s which has since become a leader in the industry. Through experience within the Li-ion battery supply chain, ReCharge has developed relationships with government and industry for distribution of key materials from industrial processors and mines, to provide OEMs and battery makers with a high-quality, high-volume and stable supply of materials needed for production of Li-ion batteries.

Graphex has extensive commercial experience producing battery grade purified spherical graphite to the power battery market, currently at a volume of 10,000 metric tons per annum (tpa) with intentions to expand production to 40,000 tpa over the next three years. The intent of the MOU is to evaluate joint venture opportunities (JV’s) to strategically locate, construct, and operate mid-stream graphite processing facilities throughout the world to support the global electrification of mobility. Whether near graphite mining resources or locations close to point-of-use - namely battery gigafactories and EV OEMs in the US and Europe. Graphex and ReCharge will leverage shared expertise in technology, design, financing, equipment sourcing, and plant operations along with established upstream and downstream relationships with key stakeholders and companies in the automotive and battery industries to provide end-to-end stable supply of battery grade anode material for EVs.

An initial focus of the collaboration will be the graphite opportunity in Australia where critical mineral mining and processing momentum is accelerating quickly. ReCharge and its affiliated companies in Australia have secured properties and/or rights to properties across the country, including first right of refusal on several projects that have the potential to produce flake graphite concentrate within 18-24 months of a quality and quantity sufficient to sustain operations of mid-stream graphite processing facilities for at least 10 years. ReCharge’s relationships with state and local governments and experience in constructing and operating production facilities in the EV supply chain, coupled with Graphex’s mid-stream production experience in the transformation of graphite into battery anode material is an ideal combination to quickly ramp up stable end-to-end supply of battery grade graphite to the EV industry for years to come.

“With this collaboration, Graphex seeks to aggregate and leverage the unique professional talents, experience bases, financial resources, and industry relationships of both organizations to accelerate our strategy to secure upstream raw material sources and to continue expanding our global footprint of mid-stream production facilities,’ said John DeMaio, CEO of Graphex Technologies. “With the EV industry engaged in the truly herculean task of electrifying mobility worldwide while simultaneously building out end-to-end domestic manufacturing capabilities, the best companies to effect this transformation quickly are those with proven experience and the willingness to innovate. Graphex has that “ability with agility” and the ReCharge collaboration will give us a wider reach.”

“Together, we can provide the mine-to-battery stability and localization of supply that is needed to meet the soaring demand for the batteries that will power the electric future of transportation.” Said David Batstone, founder and Managing Director of ReCharge. “Partnering with Graphex will be a force multiplier in this effort. Raw material sources seek to participate in the mid-stream value creation and end-users seek stability of supply - Graphex/ReCharge are uniquely capable to deliver on both fronts.”

Under the JV, the two companies will first pursue mid-stream production capabilities near graphite sources in Australia. Beyond Australia, Graphex and ReCharge are exploring several additional upstream and downstream opportunities in North America and Europe to fill the enormous – and growing - gap between demand for localized supply of natural graphite anode material and the current supply chain shortcomings to meet it.

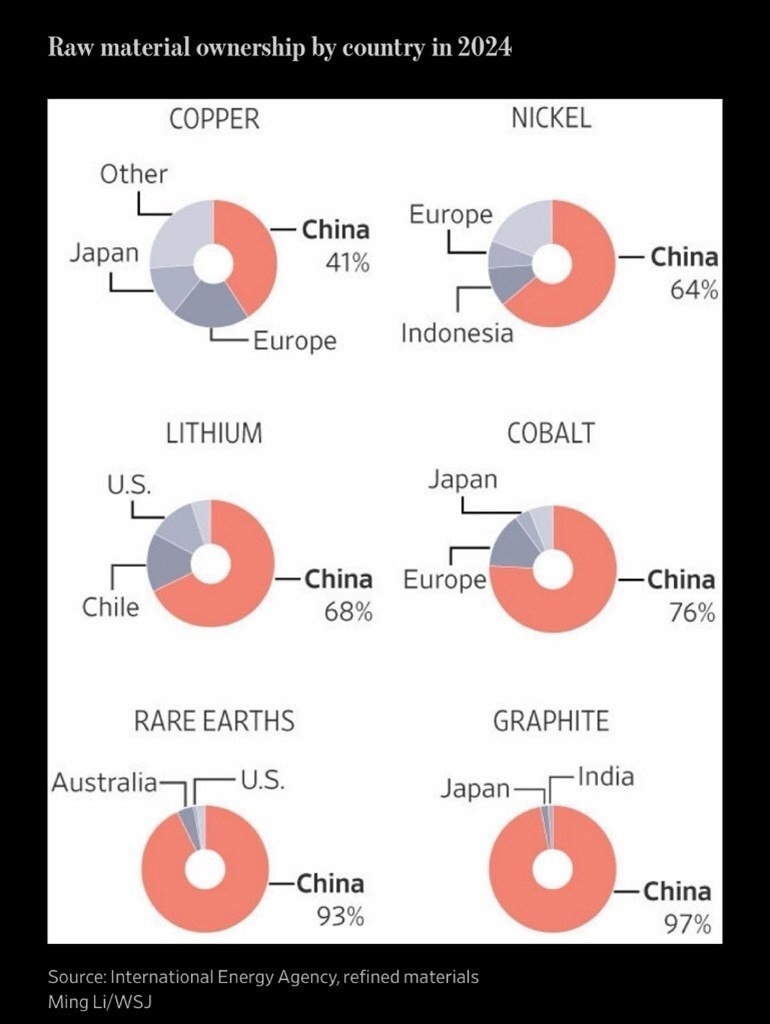

This progress in diversification and expansion follows Graphex’s recent raw material sourcing announcements around the world, including the US, Brazil, and Tanzania as well as active pursuits of additional resources in Canada, Africa, Australia, and Europe. Expanding the array of upstream resources dovetails with Graphex’s progress on a new mid-stream graphite processing facility being developed in Warren, Michigan. This scaled production and global expansion comes amidst a recent push from the USA Federal Government to stabilize American EV and battery manufacturing supply chains. As mentioned recently in the New York Times, Graphex’s stateside production and global sourcing signifies a shift in the green tech industry to extricate itself from areas of sovereign risk.

“We are proud to take the next step in globalizing our upstream and mid-stream footprint in collaboration with the industry experts at ReCharge,” added DeMaio.

About Graphex

Graphex Technologies is a wholly owned U.S. subsidiary of Graphex Group Limited, a Cayman Island company with principal and administrative offices in Hong Kong and U.S. subsidiary office in Royal Oak, MI. Graphex is focused on the development of technologies and products to enhance renewable energy, particularly the enrichment of spherical graphite and graphene, key components for EV batteries and lithium-ion batteries for other use cases. Proficient in the commercial deep processing of graphite, Graphex has extensive commercial experience producing battery grade purified spherical graphite to the power battery market, currently at a volume of 10,000 metric tons per annum (tpa) with intentions to expand production to 40,000 tpa over the next three years. With a strategy to expand its global operations to support energy transition and electrification efforts worldwide, Graphex is currently among the top suppliers of specialized spherical graphite to the EV and renewable energy industries and holds patents in areas including products, production methods, machinery design, and environmental protection.

About ReCharge

ReCharge Global Corp. provides key feedstock and minerals to European battery makers for the production of electric vehicle Lithium-Ion power batteries. We distribute materials used to form the anode, cathode and for the electrolyte. ReCharge Global was founded by the team who developed Lithium-Ion battery recycling technology for North American OEM’s, which has become one of the leaders in the industry. With the accelerated adoption of EV’s, and with almost unprecedented global government support, we identified the importance of a stable, secure mineral and key material supply for the developing battery industry. Leveraging our experience within the Lithium-Ion battery supply chain, we have developed relationships for distribution of key materials from industrial processors and mines, to provide our OEM and battery maker clients with a high-quality, high-volume and stable supply of materials needed for production of Lithium-Ion batteries

Forward Looking Statements

All statements contained in this presentation other than statements of historical fact, including statements regarding our future results of operations and financial position, our business strategy and plans and our objectives for future operations, are “forward looking statements” within the meaning of the Private Securities Litigation Reform Act of 1995 and the safe harbor in Section 27A and 21E of the Securities Act of 1933 and the Securities Exchange act of 1934, respectively. You can identify some of these forward looking statements by words or phrases such as “may,” “will,” “expect,” “anticipate,” “aim,” “estimate,” “intend,” “plan,” “believe,” “likely,” “potential,” “continue” or other similar expressions. We have based these forward-looking statements largely on our current expectations and projections about future events that we believe may affect our financial condition, results of operations, business strategy and financial needs. We have based these forward looking statements largely on our current expectations and projections about future events and trends that we believe may affect our financial condition, results of operations, business strategy, short term and long-term business operations and objectives, and financial needs. These forward looking statements involve various risks and uncertainties.

Information from third sources identified in this release are based on published reports for such information and we have assumed the accuracy of such reports without independent investigation or inquiry.

This communication is for informational purposes only and is neither an offer to sell nor a solicitation of an offer to purchase any securities of Graphex Group Limited, including but not limited to its American Depositary Shares.

Media Contact:

This email address is being protected from spambots. You need JavaScript enabled to view it.

Plug Into More Green Stock News

Tap into the pulse of emerging green sectors every morning. Top daily headlines from clean energy, cleantech, cannabis, and sustainable transport stocks:

More Green Stock News

More Green Stock News

| Last Trade: | US$0.57 |

| Daily Volume: | 0 |

| Market Cap: | US$11.990M |

November 19, 2024 August 01, 2023 June 20, 2023 | |