Plug Into More Green Stock News

Tap into the pulse of emerging green sectors every morning. Top daily headlines from clean energy, cleantech, cannabis, and sustainable transport stocks:

Harley-Davidson Factory Racing Elevates Podium Finishes with Protolabs

- New video series details how Harley-Davidson's racing team breaks course records with iterative development powered by digital manufacturing at Protolabs

MINNEAPOLIS / Sep 25, 2024 / Business Wire / It was digital manufacturing leader Protolabs’ quick-turn parts for the win in partnership with Harley-Davidson® Factory Racing. The team competes in the King of the Baggers series, a one-of-a-kind motorcycle competition bringing together the best riders in the world to race large Harley-Davidson Road Glide® motorcycles at speeds exceeding 180 mph. The racing team’s dedication to constant iteration has produced faster, nimbler bikes capable of setting course records at each stop throughout the race season. A new video series highlights Harley-Davidson’s success and its critical manufacturing partnership with Protolabs.

Harley-Davidson racing engineers depend on the digital manufacturers’ quick turn times and advanced capabilities throughout the season, often ordering and receiving parts within days and just in time for each race.

“For us to be successful in the King of the Baggers series, we need to respond rapidly to what we are learning on the racetrack, and to do that we require a partner that is able to bring these ideas to life,” said Harley-Davidson Factory Racing Team Principal Jason Kehl. “As a digital manufacturer, Protolabs allows us to make those weekly incremental improvements that lead to season-long success.”

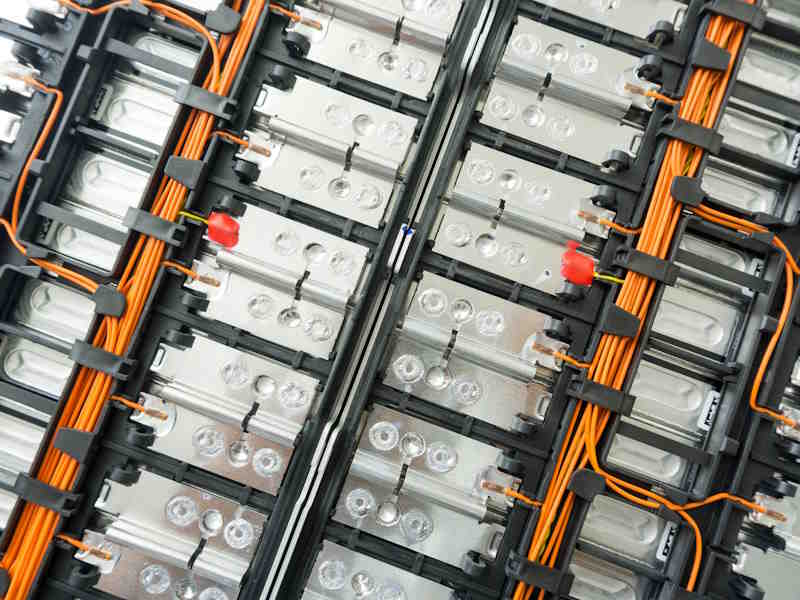

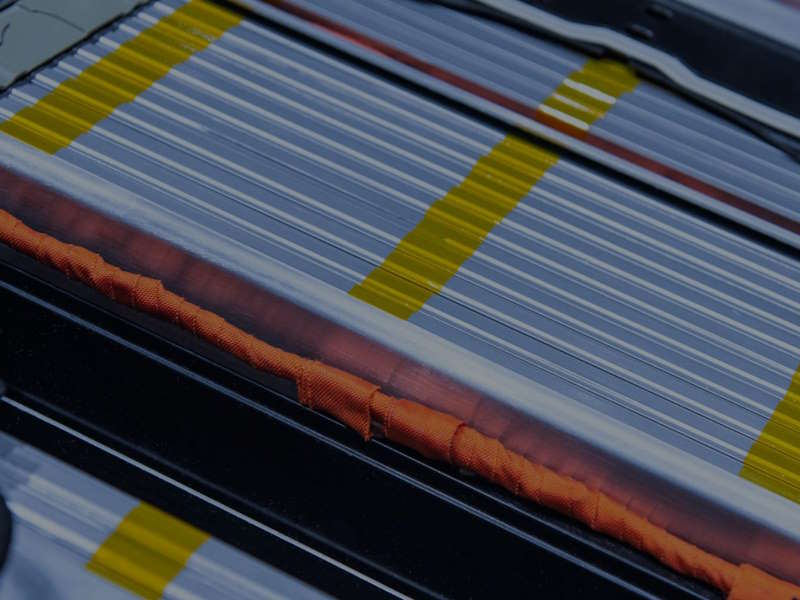

The production Harley-Davidson Road Glide weighs up to 960 lbs., while King of the Baggers bikes race at 620 lbs. The team relies on a variety of Protolabs’ manufacturing processes to implement new part designs. These changes increase speed and performance-critical lean angle while maintaining race weight. Since the race series began in 2021, Protolabs has produced injection molded, machined, sheet metal, and 3D-printed parts from its four manufacturing services. Harley-Davidson Factory Racing has not only leveraged Protolabs for quick-turn parts but also its global network of manufacturing partners for larger, complex parts.

Combining Harley-Davidson Factory Racing’s engineering team with Protolabs’ digital manufacturing expertise has allowed the team to take lessons learned from a Sunday race and translate that knowledge into a new part design. During the ensuing week, the team can prototype, test, learn, iterate, and order the final part using a race-ready lightweight material—all before the green flag drops the following weekend. The result has been significant year-over-year improvements in race times, producing podium finishes for riders Kyle Wyman and James Rispoli.

The Protolabs and Harley-Davidson Factory Racing partnership is detailed in a dynamic multimedia campaign released today that reveals how the team’s engineering expertise is leading the evolution in the King of the Baggers series. The three-part video series includes background on the Harley-Davidson Factory Racing team and two case studies diving into the development of a race-changing part:

- The Race for Record-Breaking Iteration

- Edging Out the Competition with a 3D-Printed Exhaust

- Quick-Turn Machining to the Rescue in Rain-Soaked Race

Check out the campaign by clicking here.

About Protolabs

Protolabs is the fastest and most comprehensive digital manufacturing service in the world. Our digital factories produce low-volume parts in days while Protolabs Network unlocks advanced capabilities and volume pricing through its highly vetted manufacturing partners. The result? One manufacturing source—from prototyping to production—for product developers, engineers, and supply chain teams across the globe. See what's next at protolabs.com.

Plug Into More Green Stock News

Tap into the pulse of emerging green sectors every morning. Top daily headlines from clean energy, cleantech, cannabis, and sustainable transport stocks:

More Green Stock News

More Green Stock News

| Last Trade: | US$55.00 |

| Daily Change: | 1.40 2.61 |

| Daily Volume: | 100,695 |

| Market Cap: | US$1.300B |

November 12, 2025 October 31, 2025 October 16, 2025 | |