Plug Into More Green Stock News

Tap into the pulse of emerging green sectors every morning. Top daily headlines from clean energy, cleantech, cannabis, and sustainable transport stocks:

Dragonfly Energy Completes U.S. Lithium Battery Cell Pilot Line, Begins Manufacturing Anode at Scale Using Patented Dry Deposition Processes

- Dragonfly Energy has begun successfully dry depositing anode electrodes using its patented battery manufacturing processes

- This crucial step deploys patented Dragonfly Energy technology and proves the proprietary processes work at scale, paving a path forward for domestic manufacturing of lithium batteries

- The patented processes operate within a significantly smaller manufacturing footprint and are chemistry agnostic, allowing for potential wide market expansion by the Company

- Dragonfly Energy expects to begin cathode production in the third quarter of 2023, with full cells coming off the pilot line by the end of 2023

- The pilot line is capable of domestically producing up to 150MWh of LiFePO4 battery cells annually, and production is scalable with additional production lines

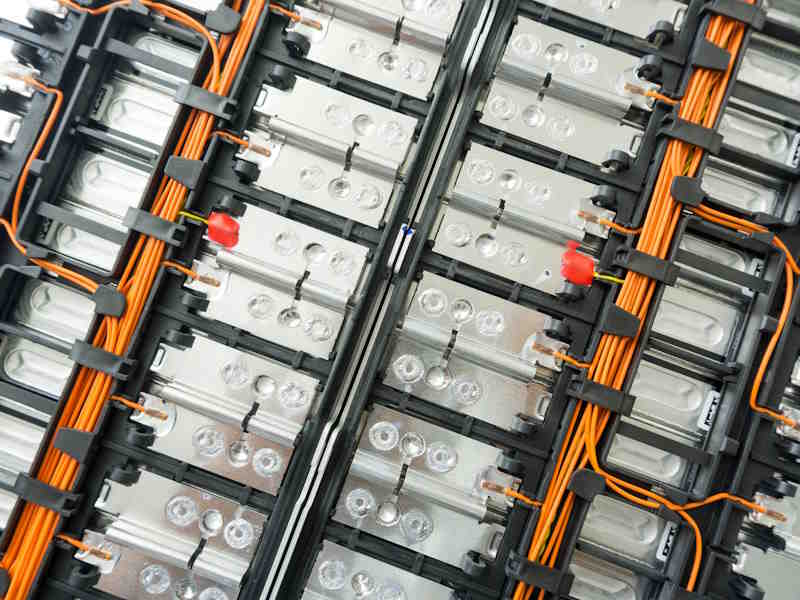

RENO, Nev., July 19, 2023 (GLOBE NEWSWIRE) -- Dragonfly Energy Holdings Corp. (Nasdaq: DFLI) (“Dragonfly Energy” or the “Company”), maker of Battle Born BatteriesTM and an industry leader in energy storage, announced today they have completed their U.S. lithium battery cell pilot line. Deploying the Company’s patented dry deposition manufacturing processes, Dragonfly Energy has begun using its pilot line to dry deposit working anode (industry standard graphite with an SBR/CMC binder), at a level sufficient to support large-scale production. The Company believes the establishment of its pilot line and the successful production of anode marks a critical milestone for its goal of manufacturing battery cells domestically from its Reno, Nevada, manufacturing facility.

Dragonfly Energy’s patented battery cell manufacturing processes are chemistry agnostic, meaning they can be applied to various uses, which is expected to enable the Company to expand into new markets over time and to achieve its goal of domestically producing nonflammable solid state battery cells. The processes allow the cells to be manufactured within a significantly smaller footprint and without the toxic solvent present in conventional cell manufacturing, which is expected to make the process not only more environmentally friendly but also more cost effective.

“Announcing that our patented dry powder coating technology is coming to fruition at scale is not only incredibly exciting on a personal level but also represents a significant turning point for the Company as we expand into cell manufacturing,” Dr. Denis Phares, Chief Executive Officer of Dragonfly Energy, said. “The implications are considerable in terms of advancing our mission of reducing the levelized cost of energy storage and establishing a closed loop domestic supply chain.”

Dragonfly Energy estimates this pilot line is capable of producing up to 150 MWh of domestically manufactured LiFePO4 (lithium iron phosphate) battery cells per year when operating at 70 percent efficiency. The Company believes it can rapidly scale capacity with additional production lines as demand increases. Using its patented dry deposition processes, the Company has been able to significantly reduce the manufacturing footprint required to produce lithium-ion battery cells by replacing large, energy intensive equipment such as slurry coaters, conveyor dryers, and solvent reclamation equipment. The new pilot line requires less than 150 square feet of physical space per electrode and consumes less than 6 kW of power. This significant reduction in energy and space is expected to meaningfully reduce the environmental impact of future battery production compared to conventional manufacturing.

Having demonstrated the scalability of the new manufacturing process with the production of anode material, the pilot line is expected to begin producing cathode material during the third quarter of 2023. With these important milestones, Dragonfly Energy expects to produce fully American-made battery cells from its pilot line in the fourth quarter of 2023. The Company expects to provide sample cells to potential customers at that time and expects to commercialize the cells by incorporating them into new Battle Born BatteriesTM products during 2024. With a well-established brand and customer base, the Company believes it is in a prime position to be able to not only market American-made battery cells, but also incorporate them into its existing and future battery products, reducing the Company’s reliance on imported cells and vertically integrating its battery production.

To learn more about Dragonfly Energy, visit DragonflyEnergy.com.

About Dragonfly Energy

Dragonfly Energy Holdings Corp. (Nasdaq: DFLI) headquartered in Reno, Nevada, is a leading supplier of deep cycle lithium-ion batteries. Dragonfly Energy’s research and development initiatives are revolutionizing the energy storage industry through innovative technologies and manufacturing processes. Today, Dragonfly Energy’s non-toxic deep cycle lithium-ion batteries are displacing lead-acid batteries across a wide range of end-markets, including RVs, marine vessels, off-grid installations, and other storage applications. Dragonfly Energy is also focused on delivering an energy storage solution to enable a more sustainable and reliable smart grid through the future deployment of its proprietary and patented solid-state cell technology. To learn more, visit www.dragonflyenergy.com/investors.

Forward-Looking Statements

This press release contains forward-looking statements within the meaning of the United States Private Securities Litigation Reform Act of 1995. Forward-looking statements include all statements that are not historical statements of fact and statements regarding the Company’s intent, belief, or expectations, including, but not limited to, statements regarding the Company’s manufacturing processes, the Company’s future results of operations and financial position, planned products and services, business strategy and plans, market size and growth opportunities, competitive position and technological and market trends. Some of these forward-looking statements can be identified by the use of forward-looking words, including “may,” “should,” “expect,” “intend,” “will,” “estimate,” “anticipate,” “believe,” “predict,” “plan,” “targets,” “projects,” “could,” “would,” “continue,” “forecast” or the negatives of these terms or variations of them or similar expressions.

These forward-looking statements are subject to risks, uncertainties, and other factors (some of which are beyond the Company’s control) which could cause actual results to differ materially from those expressed or implied by such forward-looking statements. Such factors include those set forth in the sections entitled “Risk Factors” and “Cautionary Note Regarding Forward-Looking Statements” in the Company’s Annual Report on Form 10-K for the year ended December 31, 2022 and in the Company’s subsequent filings with the SEC available at www.sec.gov.If any of these risks materialize or any of the Company’s assumptions prove incorrect, actual results could differ materially from the results implied by these forward-looking statements. There may be additional risks that the Company presently does not know or that it currently believes are immaterial that could also cause actual results to differ from those contained in the forward-looking statements. All forward-looking statements contained in this press release speak only as of the date they were made. Except to the extent required by law, the Company undertakes no obligation to update such statements to reflect events that occur or circumstances that exist after the date on which they were made.

Investor Relations

Sioban Hickie, ICR, Inc.

This email address is being protected from spambots. You need JavaScript enabled to view it.

Media Relations

Amy Demuth, RAD Strategies Inc.

This email address is being protected from spambots. You need JavaScript enabled to view it.

Plug Into More Green Stock News

Tap into the pulse of emerging green sectors every morning. Top daily headlines from clean energy, cleantech, cannabis, and sustainable transport stocks:

More Green Stock News

More Green Stock News

| Last Trade: | US$4.01 |

| Daily Change: | 0.08 2.06 |

| Daily Volume: | 639,015 |

| Market Cap: | US$48.450M |

December 10, 2025 December 08, 2025 November 28, 2025 November 24, 2025 | |