Plug Into More Green Stock News

Tap into the pulse of emerging green sectors every morning. Top daily headlines from clean energy, cleantech, cannabis, and sustainable transport stocks:

Aqua Metals Successfully Delivers Sustainable Nickel Recycling for Circular Domestic Supply of Critical Battery Metal

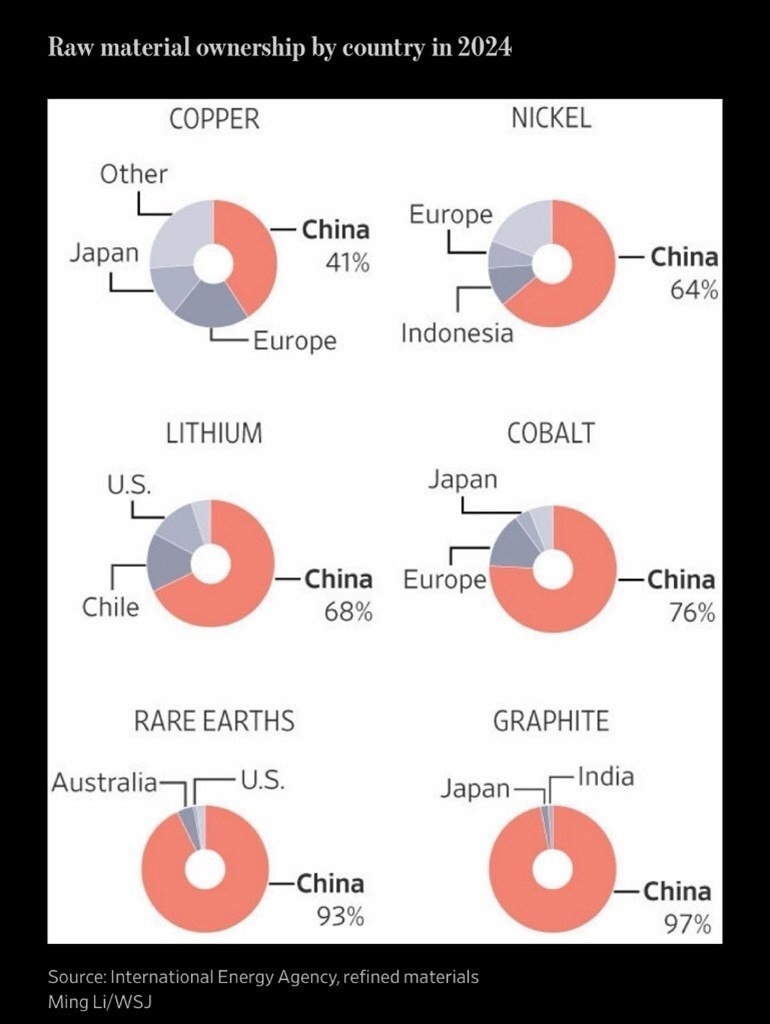

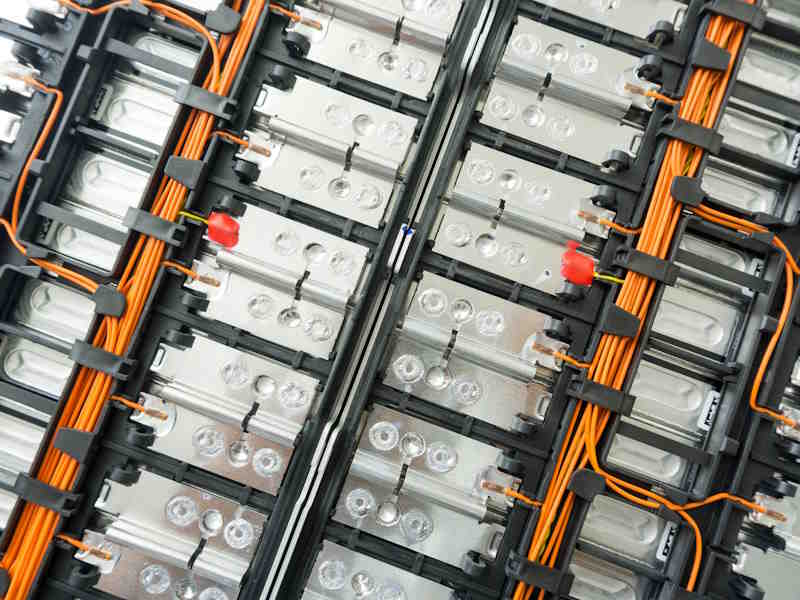

RENO, Nev., March 14, 2023 (GLOBE NEWSWIRE) -- Aqua Metals, Inc. (NASDAQ: AQMS) (“Aqua Metals" or the "Company”), a pioneer in sustainable lithium-ion battery recycling, today announced it has successfully recovered high-purity nickel from lithium battery black mass using Aqua Metals’ proprietary Li AquaRefining™ process, utilizing electricity, and without a polluting smelter or the significant chemical waste typical in recycling. The Company’s unique solution for recovering all valuable metals in lithium battery recycling supports a circular supply chain for manufacturing, and positions Aqua Metals to play an important role in meeting the growing demand for sustainably produced domestic metals.

Aqua Metals’ Li AquaRefining™ technology recovers nickel and other valuable metals using an innovative application of electroplating in a closed-loop, eliminating the need for energy-intensive and wasteful chemical processes that increase the cost and the resulting pollution of recycling. Nickel is an essential resource in the global push for electrification and clean energy technologies, and often makes up a substantial portion of the cost in electric vehicle batteries and energy storage systems. Aqua Metals also recently announced recovery of high purity lithium hydroxide and copper from ‘black mass’ at its operational pilot facility located in the Tahoe-Reno Industrial Center.

“Aqua Metals continues to drive clean battery recycling forward, and recovering high purity nickel without a polluting smelter or train loads of one-time-use chemicals and costly waste streams is a landmark achievement for the industry,” said Steve Cotton, Aqua Metals' President and CEO. “Our modular recycling pilot is proving out our vision for low-cost, sustainable lithium battery recycling and the ability to rapidly scale our novel solution to meet the surging demand for the domestic minerals essential to battery manufacturing.”

Having already demonstrated successfully at both the lab and bench scales, the Aqua Metals’ Li AquaRefining™ Pilot is now the only operational electro-hydrometallurgy lithium battery recycling facility in North America.

Current commercial lithium battery recycling methods use an energy intensive smelting process that involves high temperatures, produces toxic fumes that must be mitigated, and is unable to recover usable lithium or manganese. Proposed hydrometallurgy recycling consumes tons of hazardous chemicals, producing landfill waste and significant environmental impact from the production and transport of the one-time-use chemicals.

“Cost-effective and sustainable battery recycling cannot be achieved if each ton recovered requires multiple tons of chemicals and results in tons of waste and pollution,” said Ben Taecker, Chief Engineering and Operations Officer at Aqua Metals. “Using AquaRefining we can eliminate these hazards, which creates a safer work environment, minimizes transport of chemicals, and demonstrates our commitment to equitable and responsible recycling that benefits our community.”

Aqua Metals is currently scaling operations at its Li AquaRefining Pilot facility and is ramping up production of high-value products like pure nickel, copper, and lithium hydroxide. The Company recently announced plans for the development of an integrated clean metals recycling campus, and is currently commissioning a 3,000 ton per year commercial recycling facility on the five-acre site as the first phase of the expansion.

Additional Resources

Learn more about Aqua Metals’ Li AquaRefining Pilot and see updates at www.aquametals.com/pilot-recycling-hub

About Aqua Metals

Aqua Metals, Inc. (NASDAQ: AQMS) is reinventing metals recycling with its patented AquaRefining™ technology. The company is pioneering a sustainable recycling solution for materials strategic to energy storage and electric vehicle manufacturing supply chains. AquaRefining™ is a low-emissions, closed-loop recycling technology that replaces polluting furnaces and hazardous chemicals with electricity-powered electroplating to recover valuable metals and materials from spent batteries with higher purity, lower emissions, and minimal waste. Aqua Metals is based in Reno, NV and operates the first sustainable lithium battery recycling facility at the company’s Innovation Center in the Tahoe-Reno Industrial Center.

To learn more, please visit www.aquametals.com

Aqua Metals Social Media

Aqua Metals has used, and intends to continue using, its investor relations website (https://ir.aquametals.com), in addition to its Twitter, LinkedIn and YouTube accounts at https://twitter.com/AquaMetalsInc (@AquaMetalsInc), https://www.linkedin.com/company/aqua-metals-limited and https://www.youtube.com/channel/UCvxKNWcB69K0t7e337uQ8nQ respectively, as means of disclosing material non-public information and for complying with its disclosure obligations under Regulation FD.

Safe Harbor

This press release contains forward-looking statements concerning Aqua Metals, Inc. Forward-looking statements include, but are not limited to, our plans, objectives, expectations and intentions and other statements that contain words such as "expects," "contemplates," "anticipates," "plans," "intends," "believes", "estimates", "potential" and variations of such words or similar expressions that convey the uncertainty of future events or outcomes, or that do not relate to historical matters. The forward-looking statements in this press release include our expectations for our pilot recycling plant, our ability to recycle lithium-ion batteries and the expected benefits of recycling lithium-ion batteries. Those forward-looking statements involve known and unknown risks, uncertainties, and other factors that could cause actual results to differ materially. Among those factors are: (1) the risk that we may not be able to acquire the funding necessary to develop our recently acquired five-acre campus; (2) the risk that we may not be able to develop the recycling facility on the five-acre campus within the expected time or at all; (3) even if we are able to develop the recycling facility, the risk that we may not realize the expected benefits; (4) the risk that licensees may refuse or be slow to adopt our AquaRefining process as an alternative in spite of the perceived benefits of AquaRefining; (5) the risk that we may not realize the expected economic benefits from any licenses we may enter into; and (6) those other risks disclosed in the section "Risk Factors" included in our Annual Report on Form 10-K filed on March 9, 2023. Aqua Metals cautions readers not to place undue reliance on any forward-looking statements. The Company does not undertake and specifically disclaims any obligation to update or revise such statements to reflect new circumstances or unanticipated events as they occur, except as required by law.

Contact Information:

Investor Relations

Bob Meyers & Rob Fink

FNK IR

646-878-9204

This email address is being protected from spambots. You need JavaScript enabled to view it.

Media

Jennifer Johnson Avril

Warner Communications

917-982-9012

This email address is being protected from spambots. You need JavaScript enabled to view it.

Source: Aqua Metals

Plug Into More Green Stock News

Tap into the pulse of emerging green sectors every morning. Top daily headlines from clean energy, cleantech, cannabis, and sustainable transport stocks:

More Green Stock News

More Green Stock News

| Last Trade: | US$5.82 |

| Daily Change: | 0.01 0.17 |

| Daily Volume: | 31,521 |

| Market Cap: | US$17.340M |

November 12, 2025 November 10, 2025 November 03, 2025 October 15, 2025 September 16, 2025 | |